By: Steve Reilly

Now that every news article includes the words ‘testing’ and ‘infections’, we’re all looking for distraction from this health crisis. Over here at Aeronaut, we thought we’d explain how we use similar science to check on the health of all our yeast. If you can’t escape stories about nasty microbes, why not at least read one that ends in fantastic beer?

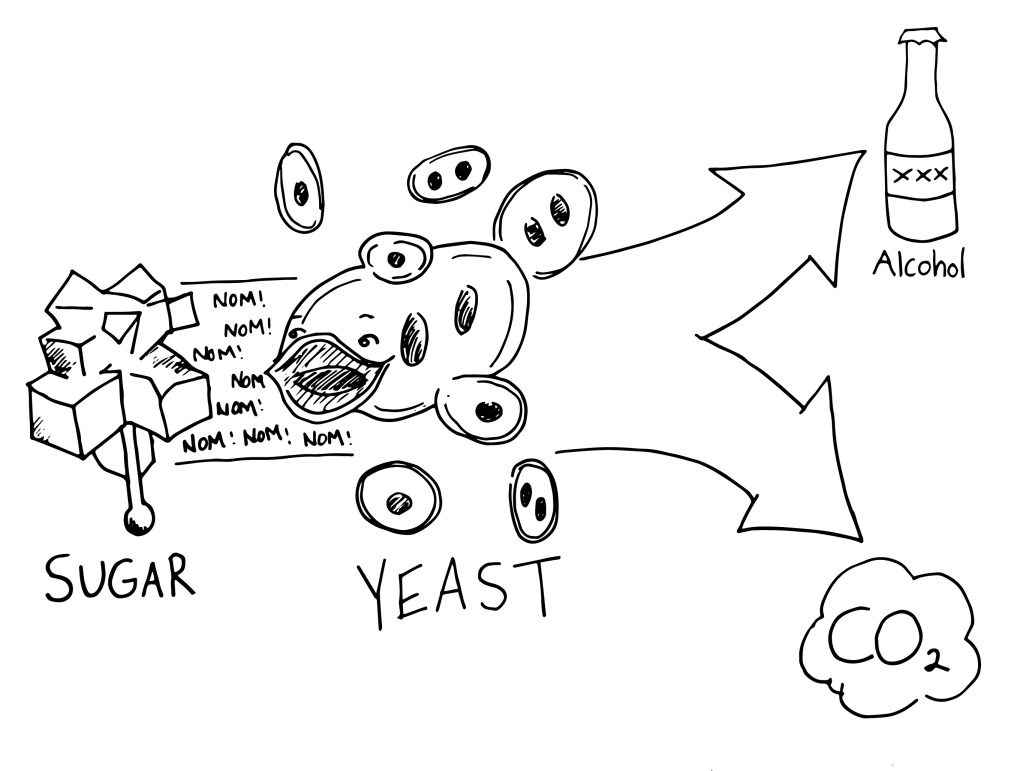

Beer is essentially the byproduct of a romance between yeast and sugars. Two friendly yeast species have been employed by humans for thousands of years: one for ales (Saccharomyces cerevisiae for the scientifically inclined among you), and a closely related cousin for lagers (Saccharomyces uvarum). Both strains of yeast devour sugar, converting it into alcohol, carbon dioxide, and a molecular zoo of other byproducts that impart unique flavors ranging from bananas to spicy cloves.

No compelling romance is without a little danger. Trouble lurks for our happy workers S. cerevisiae and S. uvarum around nearly every corner. Lactic acid-producing bacteria (such as Pediococcus) are looking to steal our yeast’s lunch and eat the sugars for themselves. Many of these bacteria have even specially evolved to infect beer, withstanding even the antibacterial properties of hops! Worse yet, Pediococcus has supercharged growth compared to our yeast friends. Imagine a one-day proliferation race between a single Pediococcus and a single cerevisiae. Our yeast cell is no slowpoke, doubling every 90 minutes, so that after a whole day it has mushroomed into around 65,000 friends. But Pediococcus doesn’t take breaks, doubling every 30 minutes. At the end of 24 hours it will have literally drowned out the competition, multiplying into an army around 300 trillion friends. In this process, the bacteria has stolen all of the yeast’s nutrients, created yogurt-tasting lactic acids, expelled buttery-flavored diacetyl, and sometimes produced long sugar molecules that can make the beer ropey like snot. Yuck.

Bacteria isn’t the only infection that can fatally strike down a brew. Other species of yeast like Brettanomyces Dekkera (known as Brett to their close friends) can also spoil a beer. In some more adventurous styles of beer like sours and lambics these yeasts can have starring roles, but in the average ale they are unwelcome contaminants. To complicate matters, Brett can survive at high alcohol percentages that normally slow down S. cerevisiae. This survival takes real metabolic effort, like a hard gym session. In this workout, Brett ‘sweats’ out a ton of byproducts, among which are phenols that can leave beer tasting like a ‘wet horse blanket’ and vinegary acetic acid.

So between the double threat of fast-growing lacto bacteria and super strong Brett yeast, how do we ever expect to make high-quality beer? Infections can easily travel between tanks, ruining multiple batches in the process. In some breweries, even the yeast stocks can be contaminated, creating cycles of huge batches of defective beer. Sterilizing our equipment before each brew prevents most infections, just like washing your hands is the best thing you can do. Aeronaut labs likes to think of this just like epidemiolocal problem. We’ve started using state-of-the-art molecular diagnostics to detect and stop infections in their tracks.

We use a process called polymerase chain reaction (PCR) to detect these bacterial and yeast invaders, very similar to how doctors check for infections. This process searches out and amplifies small stretches of DNA from bacteria and yeast from a tiny sample of beer. First, a pair of primers – pieces of DNA specific only to the organisms we’re interested in – bind to the edges of these DNA stretches in the microbial genomes we want to detect. DNA polymerase comes in next to amplify this invading DNA, making millions of copies of any DNA in-between the primers. This process takes about two hours, and at the end we’re left with either beer free of any contamination, and zero amplified bacterial DNA, or a contaminated sample that has millions of copies of these primer-amplified DNA stretches from the bacteria.

Next, we have to peer into that sample and see if there is any amplified bacterial DNA. Luckily, these primers on all the DNA are designed specifically to attract small microscopic dye spheres. When we put the reaction a strip tests of paper, if we’ve made many copies, the dye-particles will be concentrated into a single line visible to the naked eye. No bacteria = no DNA amplification = no dye line–sort of like a pregnancy test for beer. We can use a whole set of different primer sets and tests for each contaminant we’re looking for.

We test our beer at Aeronaut during many stages using a PCR detection setup. First, all the yeast that we crop (yeast harvested during fermentation to reuse) and pitch (yeast added to raw unfermented beer) gets tested right here in our lab. Conditioned beers, brews that are barrel or cask aged, are especially vulnerable to contamination, so those get tested as well. Lastly, all beer that gets canned goes for testing. Of course a brewery started by scientists would be geeking out on testing everything we can about our yeast, but we hope you can see the final result in the consistent quality of the beer!

Hopefully this has been an enlightening look into how we make sure our beer is the highest quality and free from any foul-tasting contaminants. These tests for infections in beer are based on the same fundamental principles as tests for human viruses and bacteria. If it’s any solace, in Boston where scientists are everywhere (even running a brewery) tons of people are trained to do them. Here’s to a day soon when swabs, pathogens, and PCR is the last thing on our minds as we’re enjoying a delicious beer together.

Steve Reilly is currently a researcher at the Broad institute of Harvard and MIT where he studies genomics and evolution, he is also a co-owner at Aeronaut.

Illustrations by Brit Weidel